Buy a reliable hot water pressure washer at Universal Trailer. We are conveniently located in Pacoima, CA, and Conway, SC.

TLDR: Unlock superior cleaning power with a hot water pressure washer. This guide from Universal Trailer and American Water Works explains how heated pressure washing cuts through tough grime, boosts efficiency, and sanitizes surfaces for commercial and industrial use. Find your perfect solution today.

There’s nothing quite like watching years of stubborn grease disappear in seconds. A maintenance crew at a busy trucking depot had been battling the same oil-stained loading dock for months with their cold water system. Hours of scrubbing, gallons of degreaser, and plenty of frustrated workers later, they were getting nowhere fast. Then they switched to our hot water pressure washer from Universal Trailer and American Water Works – and suddenly, what used to take half a day was done in under an hour.

That’s the power of heat in action.

TABLE OF CONTENTS

How Does a Hot Water Pressure Washer Work, and What Makes it So Effective?

A hot water pressure washer operates on a simple but powerful principle: heat dramatically accelerates the chemical breakdown of stubborn contaminants. Like the dishes in your sink, hot water “melts” grease and grime; cold water only pushes it around.

The magic happens inside the unit’s heating system. Whether powered by diesel, natural gas, propane, or electricity, the burner heats water to temperatures typically ranging from 180°F to 200°F before it reaches the high-pressure pump. This heated water then gets pressurized and delivered through your spray gun with the same PSI and GPM you’d expect from any commercial system.

But here’s where things get interesting. Every 50°F increase accelerates the chemical processes and halves reaction times. Oil, grease, and soot are dislodged and removed more easily. That means you’re not just cleaning faster – you’re cleaning more thoroughly with less effort.

At Universal Trailer and American Water Works, we’ve seen this science in action countless times. Our commercial clients consistently report 50-70% reduction in cleaning time when they upgrade from cold water systems to our heated pressure washers. The heat breaks molecular bonds in grease and oil, allowing them to emulsify and rinse away instead of just being pushed around the surface.

The heating system itself consists of a combustion chamber, heat exchanger coils, and sophisticated temperature controls. We ensure every hot water pressure washer in our inventory meets strict safety standards while delivering consistent, reliable performance for years of heavy-duty use.

What's the Difference Between a Hot Water Pressure Washer and a Cold Water Unit?

The differences go way beyond just temperature. While cold water pressure washers excel at removing loose dirt, mud, and surface contaminants, they meet their match when facing oil-based substances. Hot water washers excel at breaking down greasy and oily substances, while cold water washers are more suited for general cleaning tasks.

Think of it this way: cold water pressure washing is like trying to wash dishes with cold water alone – you’ll move the grease around, but you won’t eliminate it. Hot water dissolves these substances at the molecular level.

Performance Differences

- Cleaning Speed: Hot water systems typically reduce cleaning time by 40-60% on greasy surfaces

- Chemical Usage: Heated pressure washing often requires 25-50% less detergent

- Sanitization: Pressure washing with hot water can both clean and partially disinfect surfaces by killing many germs

- Versatility: Hot water units can handle everything cold water can, plus oil, grease, and organic stains

Cost Considerations

Cold water units have lower upfront costs and simpler maintenance requirements. However, our customers at Universal Trailer consistently find that the time savings and superior results from a hot water pressure washer deliver better long-term value, especially in commercial applications where labor costs add up quickly.

The key is matching the right system to your specific cleaning challenges. Our technical team helps customers evaluate their cleaning requirements and choose the most cost-effective solution for their operations.

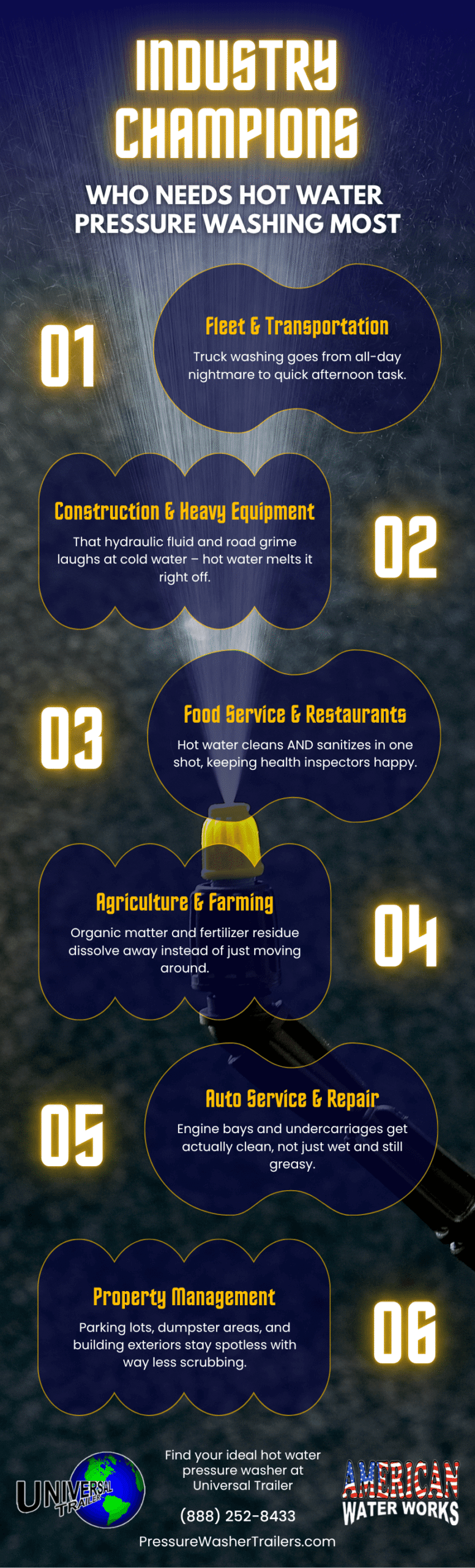

What Industries Benefit Most from a Hot Water Pressure Washer?

Some industries simply can’t function effectively without the power of heated pressure washing. We’ve supplied hot water pressure washer systems to diverse sectors, each with unique cleaning challenges that hot water solves beautifully.

Heavy Equipment and Construction

Construction sites generate some of the toughest cleaning challenges imaginable. Heavy machinery arrives caked with mud, hydraulic fluid, and grease that’s been baking in the sun for hours. Cold water barely makes a dent, but a hot water pressure washer cuts through this mess like butter.

Fleet maintenance operations particularly benefit from heated systems. Hot water effectively dissolves and removes grease, oil, and stubborn stains from your car’s surfaces. The heat accelerates the cleaning process, reducing the time and effort required for thorough cleaning.

Food Service and Agriculture

Temperature matters tremendously in food-related industries. Restaurants, food processing facilities, and agricultural operations need more than just clean – they need sanitized. Hot water pressure washing provides both deep cleaning and partial sanitization in one step.

Agricultural equipment faces unique challenges with organic matter, fertilizers, and pesticide residues. The heat helps break down these substances while reducing the need for harsh chemical cleaners that could impact soil or water systems.

Manufacturing and Industrial Facilities

Manufacturing facilities deal with cutting oils, hydraulic fluids, and industrial lubricants that laugh at cold water attempts. Our hot water pressure washer systems have become essential tools for maintaining clean, safe work environments in machine shops, auto plants, and manufacturing facilities across the country.

The ability to quickly clean production equipment between shifts or product changeovers can dramatically improve operational efficiency. We’ve worked with facilities that cut their cleaning downtime in half after switching to our heated pressure washing systems.

Each industry has specific GPM, PSI, and temperature requirements. That’s why we maintain such an extensive inventory at Universal Trailer and American Water Works – because one size definitely doesn’t fit all when it comes to commercial cleaning equipment.

Choosing the Right Hot Water Pressure Washer for Your Business

Selecting the perfect hot water pressure washer involves balancing several key factors. We guide our customers through this process every day, and there are some crucial considerations that make all the difference.

Pressure and Flow Rate Matching

The old “more is better” approach doesn’t always apply. A 4000 PSI, 4 GPM system might sound impressive, but if you’re cleaning delicate surfaces or working in tight spaces, you might be better served with a 2500 PSI, 5 GPM setup that covers more area with gentler pressure.

Fuel Type Selection

- Diesel: Best for outdoor applications and mobile units. Excellent fuel efficiency and widely available.

- Natural Gas: Ideal for stationary installations with gas lines. Lower operating costs and cleaner burning.

- Propane: Perfect balance of portability and clean burning. Easy to monitor fuel levels.

- Electric: Quiet operation for indoor use or noise-sensitive areas. Zero direct emissions.

Mobility Requirements

We offer everything from compact portable units to full trailer-mounted systems. Trailer-mounted hot water pressure washer units provide maximum power and water capacity for large-scale operations, while portable units offer flexibility for varied job sites.

Temperature Control Features

Professional-grade systems include precise temperature controls, safety shutoffs, and burner protection systems. These features aren’t just conveniences – they’re essential for reliable operation and operator safety.

Our team at Universal Trailer and American Water Works takes the guesswork out of this selection process. We evaluate your specific cleaning challenges, site requirements, and budget constraints to recommend the ideal system configuration.

Maintenance and Safety Best Practices for Hot Water Systems

A well-maintained hot water pressure washer will serve you reliably for years, but these systems do require more attention than their cold water counterparts. The good news is that proper maintenance isn’t complicated – it just needs to be consistent.

Daily Maintenance Routine

Start each day by checking fuel levels, water supply, and basic system functions. Always allow the burner to cool completely before performing any maintenance. This simple habit prevents 90% of common issues we see in the field.

Molecular Activity Acceleration

Heat increases molecular movement, which accelerates chemical reactions. When hot water contacts oil or grease, it increases the kinetic energy of both substances, causing faster breakdown and emulsification. This isn’t just theory – it’s measurable science that translates directly to faster, more thorough cleaning.

Solubility Enhancement

Many substances that resist cold water dissolve readily in hot water. Waxes, animal fats, and petroleum-based products all become more soluble as temperature increases. This means contaminants actually dissolve into the water rather than just being moved around.

Detergent Effectiveness

Hot water dramatically improves detergent performance. Surfactants work more efficiently at elevated temperatures, meaning you can achieve better results with less chemical usage. Our customers routinely report 30-50% reduction in cleaning chemical costs after switching to heated pressure washing.

Surface Penetration

Heat helps cleaning solutions penetrate deeper into porous surfaces. This is particularly important when cleaning concrete, unsealed wood, or textured metal surfaces where contaminants can hide in microscopic pores.

The combination of heat, pressure, and flow rate creates a cleaning synergy that’s impossible to achieve with cold water alone. Hot water offers extra cleaning power when you need it most.

At Universal Trailer and American Water Works, we’ve invested heavily in understanding this science because it helps us recommend the right hot water pressure washer configuration for each customer’s specific needs.

Quick Checklist: Choosing the Right Hot Water Pressure Washer for Your Business

Essential Specifications to Consider:

- PSI Requirements: Match pressure to your most delicate surfaces to avoid damage

- GPM Needs: Higher flow rates clean larger areas faster but require more water supply

- Temperature Range: Most applications need 180-200°F; food service may require higher

- Fuel Availability: Choose fuel type based on site access and operational preferences

Operational Factors:

- Mobility Needs: Stationary, portable, or trailer-mounted configurations

- Water Supply: Ensure adequate flow rate and pressure for your chosen system

- Power Requirements: Match electrical needs to available site power

- Storage Space: Factor in fuel storage and equipment protection requirements

Budget Considerations:

- Initial Investment: Hot water systems cost $3,000-8,000 more than equivalent cold water units

- Operating Costs: Factor in fuel, maintenance, and potential chemical savings

- ROI Timeline: Most commercial operations see payback within 12-18 months

- Financing Options: Ask about equipment financing and lease programs

Our recommendation is to always size slightly above your current needs – businesses grow, and cleaning requirements typically expand over time.

Myth vs. Fact: Common Misconceptions About Hot Water Pressure Washing

Myth: Hot water pressure washers are too expensive to justify.

Fact: While upfront costs are higher, the time savings and reduced chemical usage typically provide ROI within 12-18 months for commercial operations.

Myth: You can just add hot water to any pressure washer.

Fact: Regular pressure washers lack the reinforced seals, heat-resistant components, and safety systems required for hot water operation. Attempting this can cause serious damage and safety hazards.

Myth: Hot water systems are too complicated for small businesses.

Fact: Modern hot water pressure washer systems feature automatic controls and safety systems that make operation as simple as cold water units.

Myth: The maintenance requirements make hot water systems impractical.

Fact: With proper training and routine care, maintenance requirements are manageable and the improved cleaning performance more than compensates for the additional attention needed.

These misconceptions often prevent businesses from realizing the benefits of heated pressure washing. Our team at Universal Trailer works with customers to separate fact from fiction and make informed equipment decisions.

Case Study: How a Fleet Maintenance Company Slashed Cleaning Time by 50%

Regional Transport Solutions operated a 200-vehicle fleet with a constant stream of trucks requiring cleaning between routes. Their cold water system required 45 minutes per vehicle, plus significant chemical usage for degreasing.

After consulting with our team, they upgraded to an American Water Works trailer-mounted hot water pressure washer system with 4 GPM flow rate and 3000 PSI pressure. The results were immediate and dramatic:

- Cleaning Time: Reduced from 45 minutes to 20 minutes per vehicle

- Chemical Usage: Decreased by 60% due to hot water’s superior degreasing ability

- Labor Efficiency: Allowed reallocation of two part-time positions to other duties

- Customer Satisfaction: Vehicles consistently achieved higher cleanliness standards

The system paid for itself in 14 months through time savings alone, not counting the chemical cost reductions and improved operational efficiency.

This success story illustrates why we’re passionate about helping businesses discover the transformative power of professional hot water pressure washer systems.

Your Next Steps with Universal Trailer and American Water Works

Choosing the right hot water pressure washer is an investment in your business’s efficiency and cleaning effectiveness. We’ve built our reputation by helping commercial and industrial customers find exactly the right solution for their specific challenges.

Our extensive inventory includes systems from leading manufacturers like American Water Works, Alkota, All American, and Hotsy, all backed by our comprehensive service and support network. Whether you need a compact portable unit for varied job sites or a high-capacity trailer mounted pressure washer for heavy-duty operations, we have the expertise and equipment to meet your needs.

Don’t let stubborn grease and grime slow down your operations. The cleaning power of hot water can transform your efficiency and results. Contact our technical specialists today to discuss your specific requirements and discover how a hot water pressure washer from Universal Trailer and American Water Works can revolutionize your cleaning operations.

Frequently Asked Questions

Diesel offers excellent efficiency for mobile units, while natural gas provides lower operating costs for stationary installations. The best choice depends on your specific application and fuel availability.

Daily fuel and water checks, regular fuel filter replacement, heat exchanger descaling, and proper winter storage are essential. Follow manufacturer schedules and use quality fuel and water sources.

Essential accessories include appropriate nozzles for your applications, quality hoses rated for high temperature, surface cleaners for large areas, and proper chemical injection systems.

Yes, we offer various financing options for qualified commercial customers. Our team can help structure payment plans that align with your cash flow and budget requirements.

Most applications achieve optimal results between 180-200°F. Food service applications may require higher temperatures, while some delicate surfaces need lower temperatures to prevent damage.

PSI (pressure) provides impact force for breaking contaminant bonds, while GPM (flow rate) determines coverage area and rinsing power. Both work together for optimal cleaning performance.

Electric-heated units can be used indoors with proper ventilation. Fuel-burning units require outdoor operation or specially designed ventilation systems due to combustion exhaust.

With proper maintenance, quality commercial units typically provide 8-15 years of reliable service. The burner system may require overhaul every 5-7 years depending on usage intensity.

Disclaimer: Equipment specifications and performance capabilities may vary based on specific configurations and operating conditions. Professional consultation is recommended for custom applications and specialized requirements. Regulatory compliance requirements vary by location and application – consult local authorities for specific permit and operational requirements.