TLDR: Need a professional pressure washing rig? Universal Trailer and American Water Works design custom, turnkey mobile systems with top brands like Hotsy, American Water Works, All American, and Alkota. Get thousands of hours of reliable cleaning power for your commercial operations.

Jake’s old setup was a nightmare. Three separate pieces of equipment, extension cords everywhere, a garden hose that couldn’t keep up, and a pressure washer that overheated every two hours. He was losing money on every job because he spent half his time troubleshooting instead of cleaning. Then he invested in a complete pressure washing rig from Universal Trailer and American Water Works. Everything changed. His first fleet washing contract went so smoothly that the client doubled their order on the spot.

That’s the difference between cobbling together equipment and investing in a purpose-built mobile cleaning system. When your livelihood depends on showing up to a job site ready to perform, a professional pressure washing rig isn’t just convenient—it’s essential.

TABLE OF CONTENTS

What Key Components Define a Professional Pressure Washing Rig?

A commercial-grade mobile wash system is more than just a pressure washer bolted to a trailer. It’s an integrated ecosystem where every component works in harmony to deliver consistent, reliable cleaning power. Let’s break down what separates the professionals from the amateurs.

The Five Non-Negotiable Components of a Commercial Wash Rig:

- Heavy-Duty Trailer Frame – Your foundation matters. A quality rig starts with a robust trailer rated for the total weight of your equipment, water tank, and chemicals. We use commercial-grade steel frames with proper load distribution.

- Industrial Pressure Washer Unit – This is your workhorse. For most commercial jobs, you’re looking at 3,000 to 5,000 PSI paired with 3.5 to 5.0 GPM for optimal performance. Brands like Hotsy, Alkota, and American Water Works build units that can handle 10-hour days without breaking a sweat.

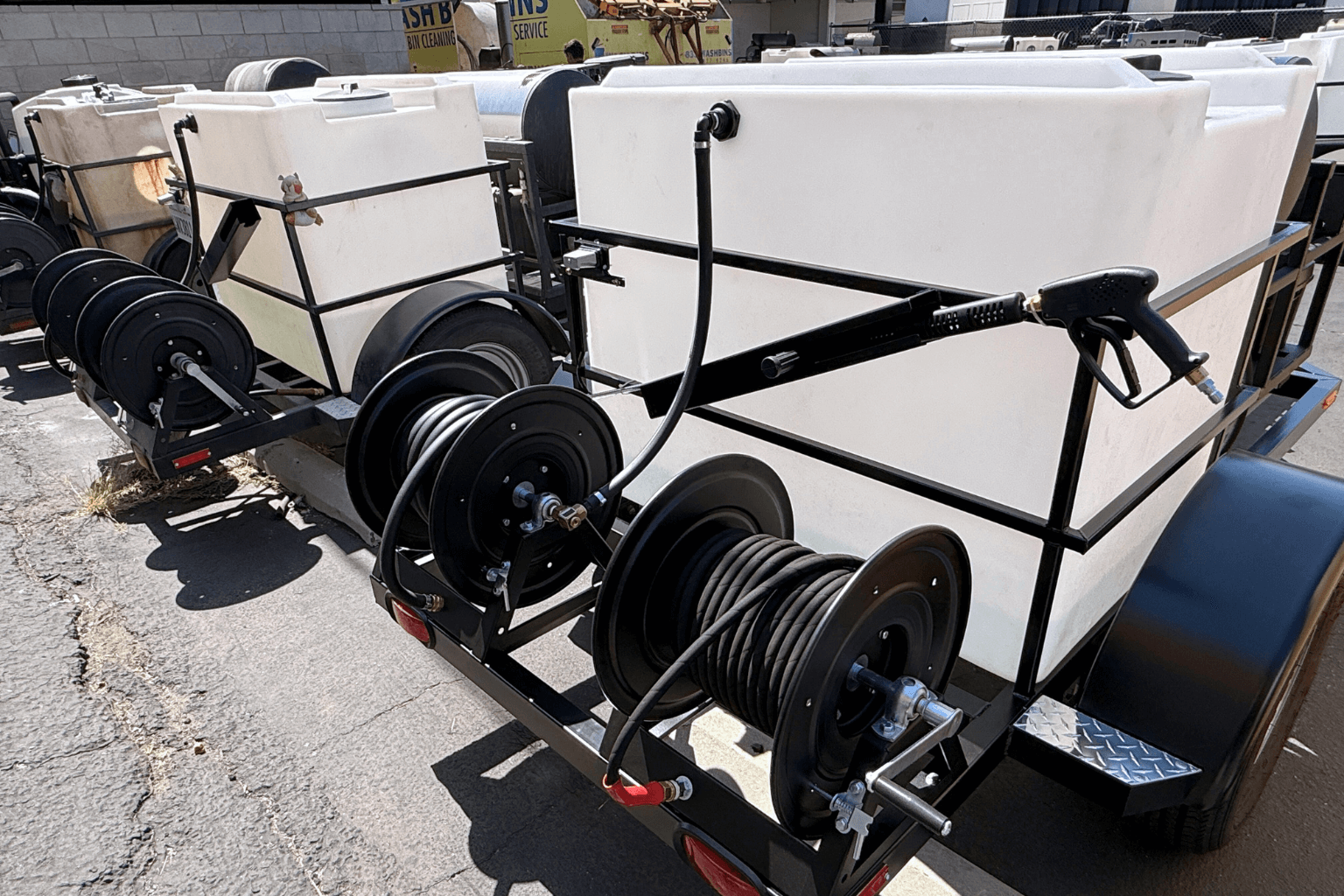

- Adequate Water Storage – Running out of water mid-job is amateur hour. Professional rigs include tanks ranging from 200 to 800 gallons, depending on your typical job requirements. This gives you independence from uncertain water sources.

- Professional Hose Reels and Plumbing – Cheap hose reels fail. Period. We install heavy-duty reels that can handle hundreds of wind-and-unwind cycles, along with industrial-grade quick connects that don’t leak or wear out after a month.

- Burner System for Hot Water – This component alone can transform your business. Hot water systems cut through grease, oil, and organic material exponentially faster than cold water alone. For restaurant exhaust cleaning, fleet degreasing, or industrial maintenance, it’s non-negotiable.

Each component needs to be properly sized and matched to the others—otherwise, you create bottlenecks that limit your system’s effectiveness and efficiency.

Hot Water vs. Cold Water: Which Pressure Washing Rig is Best for Your Cleaning Niche?

This question comes up constantly, and the answer depends entirely on what you’re cleaning. Cold water rigs have their place, but a hot water pressure washer opens up entirely different markets and commands premium pricing.

Cold water pressure washing works well for concrete cleaning, basic surface prep, and removing loose dirt and debris. It’s straightforward, requires less maintenance, and costs less upfront. For residential driveway cleaning or basic deck washing, cold water gets the job done.

But here’s where hot water changes everything. Grease doesn’t just disappear under cold water pressure—it moves around. Hot water actually breaks down oils and organic compounds at the molecular level. Restaurant exhaust hoods, industrial equipment, fleet vehicles covered in road grime—these jobs become dramatically faster and more effective with heat.

The temperature sweet spot sits between 180-200°F for most commercial applications. At these temperatures, you’re not just pushing dirt around; you’re actually dissolving contaminants. Jobs that take four hours with cold water might take ninety minutes with a hot water rig.

"The hot water system on our new rig is a game changer for restaurant exhaust cleaning. It cut our job time in half. Excellent support from American Water Works!"

David M., Industrial Maintenance

We’ve watched contractors double their revenue after upgrading to hot water systems, not because they worked longer hours, but because they could tackle more profitable jobs in less time. That’s the ROI calculation every serious operator needs to consider.

Understanding PSI and GPM: The Dynamic Duo of Cleaning Power

Here’s something most people get wrong about pressure washers: PSI gets all the attention, but GPM does half the work. PSI provides cutting power while GPM delivers rinsing power—you need both for maximum efficiency.

Think of it this way: PSI (pounds per square inch) is how hard the water hits the surface. It breaks the bond between dirt and the substrate. But GPM (gallons per minute) is the volume of water that carries that loosened dirt away. High PSI with low GPM means you’re breaking things loose but not rinsing effectively. High GPM with low PSI means you’re just getting things wet.

The sweet spot for commercial use typically falls between 3.5 to 5.0 GPM and 3,000 to 4,000 PSI. This combination gives you the punch to break through tough contaminants and the flow to rinse them away efficiently.

We often multiply PSI by GPM to get “cleaning units”—a rough measure of overall cleaning power. A 4 GPM unit at 4,000 PSI gives you 16,000 cleaning units. But remember, distribution matters. Those specifications need to match your typical cleaning applications and the surface materials you work with most often.

Maximizing Efficiency and ROI with a Turnkey Pressure Washing Rig

Let’s talk about what “turnkey” actually means when you’re investing $15,000 to $40,000 in a mobile cleaning system. It’s not just about bolting equipment to a trailer and calling it done.

A proper turnkey power washing trailer arrives at your door ready to connect to a vehicle and head to your first job. The pressure washer is mounted, plumbed, and tested. The water tank is installed with proper baffling to prevent surge. The hose reels are positioned for ergonomic access. The chemical injection systems are calibrated. The burner is tuned for your fuel type.

"Universal Trailer built the perfect pressure washing rig for our concrete business. It was ready to go the second we picked it up, and the team helped us choose the exact specs we needed."

Sarah L., Commercial Cleaning Pros

This level of preparation matters because every hour you spend troubleshooting, adjusting, or fixing your rig is an hour you’re not billing. Our customization process starts with understanding your target markets, typical job durations, and growth plans. Then we spec the components that make sense for your operation—not just what fits a generic template.

Top 3 Mistakes When Customizing a Pressure Washing Rig

- Underestimating water tank capacity – Nothing kills momentum like constant refill trips. Size your tank for your longest typical job, plus a safety margin.

- Choosing the wrong pump type – Direct-drive pumps are cheaper but wear faster under commercial loads. Triplex plunger pumps with forged brass heads and ceramic pistons last exponentially longer.

- Skimping on trailer quality – A $1,000 trailer savings means nothing when your frame cracks after six months of heavy use. Commercial-grade axles and proper weight distribution aren’t optional.

The ROI calculation is straightforward: a quality mobile wash rig lets you take bigger jobs, work more efficiently, and present a professional image that commands premium pricing. Contractors typically see payback within 12-18 months.

Building Your Custom Rig: Brand Selection and Component Quality

Not every pressure washer trailer for sale is created equal, and when your business depends on reliability, brand matters. We’ve been in this industry long enough to know which manufacturers build equipment that lasts and which ones cut corners.

At Universal Trailer and American Water Works, we’re authorized dealers for the industry’s most respected brands: Hotsy, Alkota, American Water Works, and All American. This isn’t just a sales line—authorized dealer status means we have direct factory support, genuine parts availability, and technicians trained on these specific systems.

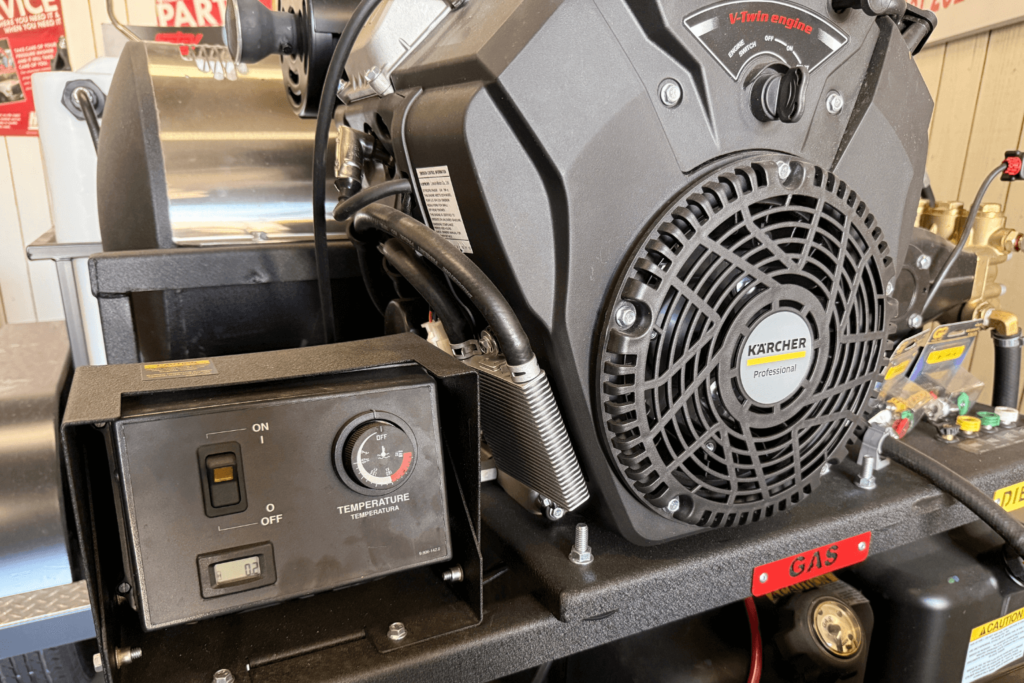

Hotsy units, for example, have earned their reputation through decades of performance in industrial environments. Their hot water systems use efficient burner designs that minimize fuel consumption while maintaining consistent temperatures. The build quality shows in components like stainless steel wrapping, schedule 80 heating coils, and industrial-grade motors.

"The Hotsy rig we bought is a beast. It handles 10-hour days like a champ. Nothing on it has failed. Worth every penny."

Mike T., Fleet Washing Services

Alkota brings similar pedigree with their focus on American manufacturing and heavy-duty construction. Their pressure washers feature robust pump assemblies, quality Honda or Vanguard engines, and burner systems designed for thousands of hours of operation.

When you’re spec’ing a custom build, we walk through engine options (Honda’s commercial GX series is the gold standard), pump configurations (CAT and General Pump are top-tier choices), and burner efficiency ratings. These decisions impact your operating costs and maintenance schedules for years to come, so they deserve careful consideration rather than price-only comparisons.

Quick Checklist: 7 Steps to Sourcing Your Ideal Mobile Wash Rig

Ready to make the investment? Here’s your systematic approach to getting the right equipment:

- Define your primary cleaning applications – Fleet washing, concrete cleaning, industrial equipment, or building exteriors? Each demands different specifications.

- Calculate your typical water usage – Multiply your average GPM by your longest job duration. Add 25% for safety margin. That’s your minimum tank size.

- Determine hot vs. cold water requirements – If more than 40% of your work involves grease or oil, hot water pays for itself quickly.

- Research insurance and liability requirements – Some contracts specify minimum equipment standards. Know these before you buy.

- Budget for the complete system – Don’t just price the pressure washer. Include trailer, tank, reels, hoses, nozzles, safety equipment, and initial chemical inventory.

- Verify dealer authorization and local service – When something breaks, you need parts and expertise fast. Authorized dealers maintain inventory and training.

- Plan for preventive maintenance – Burner systems need annual service. Pumps need oil changes. Budget time and money for keeping your rig in peak condition.

Following this process keeps you focused on business needs rather than getting distracted by features you’ll never use or overlooking capabilities you’ll desperately need six months in.

Case Study: From Handyman to Hotsy Pro – A Journey to a Custom Rig

Marcus started his cleaning business with a consumer-grade electric pressure washer and a pickup truck. He hustled hard, building a client base through excellent work and word-of-mouth. But he kept hitting the same ceiling—he couldn’t take larger commercial contracts because he lacked the equipment and water capacity.

After two years of grinding, Marcus connected with our team at Universal Trailer. We built him a custom skid-mounted system on a 16-foot tandem axle trailer: a Hotsy 4 GPM hot water unit, 500-gallon tank with proper baffling, dual hose reels with 200 feet of hose capacity each, and a complete chemical injection system.

The transformation was immediate. Marcus could now bid on restaurant cleaning contracts, fleet washing accounts, and industrial facility maintenance—markets that were completely closed to him before. His average invoice jumped from $300 to $1,200. Within fourteen months, the rig had paid for itself, and he was considering a second unit for a new employee.

That’s not a unique story. We see it repeatedly: contractors who invest in professional-grade mobile cleaning systems unlock entirely different market segments and pricing tiers. The equipment doesn’t just make you more efficient—it makes you eligible for the work that actually builds wealth.

Essential Maintenance and Longevity Tips for Your Wash Rig

A commercial pressure washing rig represents a significant investment, and like any piece of professional equipment, longevity depends on proper care. Let’s cover the critical maintenance that protects your investment.

For Hot Water Systems:

- Inspect and clean burner nozzles every 100 hours of operation

- Descale heating coils annually if working in hard water areas

- Check fuel filters and replace per manufacturer specifications

- Monitor burner combustion—proper adjustment prevents carbon buildup

For Pumps and Pressure Systems:

- Change pump oil every 500 hours or every three months, whichever comes first

- Inspect seals and replace at first sign of leaking

- Never run pumps dry—install and test low-water shutdown systems

- Use quality inlet water filtration to protect pump components

For Trailers and Mobile Components:

- Check tire pressure before every work week

- Grease wheel bearings seasonally or every 5,000 miles

- Inspect electrical connections for corrosion

- Verify all mounting bolts remain tight—vibration causes loosening

Chemical Systems:

- Flush chemical injection systems weekly with clean water

- Replace chemical metering tips annually

- Inspect chemical tanks for cracks or degradation

- Never mix incompatible cleaning agents

We recommend keeping a maintenance log with your pressure washing rig. Track hours, service dates, and any repairs. This documentation helps with warranty claims, reveals patterns before failures occur, and increases resale value when you eventually upgrade.

Professional maintenance isn’t an expense—it’s insurance against the massive cost of downtime when you have jobs scheduled and equipment fails.

Navigating Safety, Insurance, and Regulatory Requirements

Professional pressure washing isn’t just about cleaning surfaces—it involves hot water, high pressure, chemicals, and mobile equipment. That combination creates genuine liability that needs proper management.

OSHA provides clear guidelines for pressure washing operations, particularly around personal protective equipment, chemical handling, and hot water safety. Workers need eye protection, appropriate footwear, and training on high-pressure equipment hazards. Hot water systems above 180°F require specific safety protocols to prevent burns.

Insurance companies look at your equipment quality when underwriting policies. Professional-grade rigs with proper safety features (emergency shutoffs, pressure relief valves, secure chemical storage) typically get better rates than DIY cobbled setups. Some commercial contracts explicitly require proof of equipment meeting certain standards.

Environmental regulations vary by location but commonly address water reclamation, chemical runoff, and stormwater management. Many industrial and municipal contracts now require water recovery systems—something to consider when spec’ing your rig if you’re targeting those markets.

We include built-in safety features on every rig we build: pressure relief valves, temperature safety cutoffs, emergency fuel shutoffs, and secure mounting for all components. These aren’t upsells; they’re fundamental aspects of professional equipment that protect both operators and your business.

Taking shortcuts on safety eventually costs far more than doing it right from the start, whether through injuries, insurance claims, or lost contracts.

Why Universal Trailer and American Water Works Should Build Your Next Rig

We’ve covered the technical side—now let’s talk about why you should work with us specifically. Our expert team at Universal Trailer and American Water Works has spent decades mastering mobile pressure washing systems. We’re not a general equipment dealer who happens to sell pressure washers. This is our specialty, our focus, and our expertise.

Our authorized dealer status with Hotsy, Alkota, American Water Works, and All American means you get genuine factory parts, warranty coverage that actually works, and access to technical support when you need it. We maintain parts inventory specifically for the equipment we sell, so repair downtime is measured in hours rather than weeks.

Every custom build starts with a consultation about your business, not just a parts catalog. What markets are you targeting? What’s your growth plan? How do your current jobs break down by type and duration? These answers drive our component recommendations, ensuring you invest in capabilities you’ll actually use rather than impressive specifications you’ll never need.

We design for serviceability. Components are mounted with access in mind. Fittings use common sizes you can find anywhere. Systems are labeled clearly. When something eventually needs service (everything does eventually), you’re not trapped with proprietary connectors or impossible-to-reach components.

After installation, we don’t just hand you keys. We walk through every system, explain maintenance requirements, demonstrate proper operation, and answer questions until you’re confident. Then we’re available for technical support as you grow your operation and encounter new situations.

Professional contractors choose us because we understand their business challenges beyond just equipment. We’ve seen thousands of operations succeed and struggle. That experience informs every rig we build and every recommendation we make.

Ready to build your custom pressure washing rig? Get Expert Consultation or explore our turnkey mobile cleaning solutions today.

Frequently Asked Questions

With proper maintenance, a professional rig built with quality components like Hotsy or Alkota equipment typically delivers 3,000-5,000 hours of reliable operation, often 10+ years for contractors maintaining reasonable schedules.

Yes, most contractors finance commercial pressure washing equipment through equipment financing programs, business loans, or manufacturer financing options. We can connect you with financing partners who specialize in mobile equipment.

For most commercial applications, 3.5 to 5.0 GPM paired with 3,000 to 4,000 PSI provides the optimal balance of cleaning power and efficiency for professional operations.

Clean burner nozzles every 100 hours, change pump oil every 500 hours, descale heating coils annually, and maintain proper fuel filtration. Neglecting burner maintenance causes the majority of hot water system failures.

Generally, no—most pressure washing trailers fall under standard Class D license limits. However, check your state’s specific regulations regarding total combined weight and any commercial use restrictions.

Most commercial pressure washers require minimum 20 PSI inlet pressure and flow rates matching or exceeding the pump’s GPM rating. Onboard tanks eliminate dependence on customer water sources.

Skid units mount in truck beds or trailers and require separate transportation, offering flexibility. Trailer mounts integrate everything on a dedicated trailer for turnkey mobility—better for dedicated cleaning businesses.

New equipment includes warranties, known service history, and current technology. Used rigs can offer value but require careful inspection of pump hours, burner condition, and trailer integrity—ideally with expert evaluation.

Disclaimer: Equipment specifications and performance capabilities may vary based on specific configurations and operating conditions. Professional consultation is recommended for custom applications and specialized requirements. Regulatory compliance requirements vary by location and application – consult local authorities for specific permit and operational requirements.

One Response